IMD Fluoroplastic Magnetic Drive Pump

★Operating Temperature:-20ºC ~ 150ºC

★Flow:1m3/h ~ 400 m3/h

★Pump lift:17m ~ 80m

★Product Overview:

IMD Fluoroplastic Magnetic driven pump is the update pump of CQB Series.It is based on the technology accumulation and the study of the advancedtechnology ,we designed this high-efficiency and energy-saving magnetic pump. The features of this pump are small flow and high pump head. Pump appearance and installation dimension are according to ISO International standard design and production . All specification are motor straight connecting .the middle bracket support , compact structure ,remove

convenient. Pump imported adopts steel liner F46, moulded by high temperature . In order to enhance pump pressure resistance . Inner rotor and

the outer rotor adopts high performance magnetic materials of :"ndfeb" do

inside and outside magnet , isolation set used import non-metal materials

made , greatly reduces the magnetic eddy current loss. This Series of magnet

pump performance is remarkable , low price , in the domestic and foreign

many projects used and gain recognition, has become a substitute impored

magnetic pump first choose.

Application Field :

It can convey high concentration ,density is greater than 1.9 t/m3 of strong

corrosive medium .widely used chemical industry , petroleum ,

paper-making ,acid alkali manufacturing , pesticide ,medicine ,

inflammable ,easy to leakage, explosive liquid.

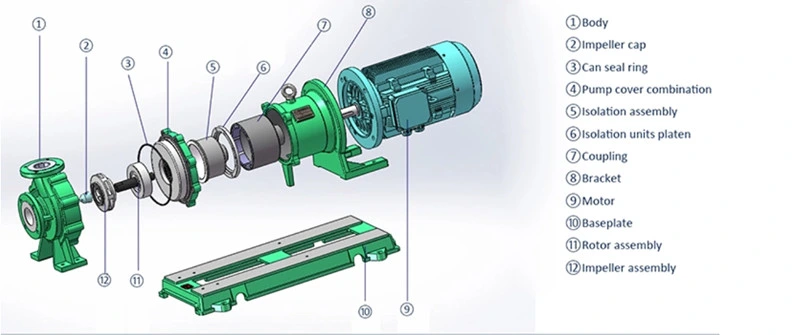

IMD series magnetic pump structure

Pump Performance Table:

Package:

Q:Can you supply pump qualified with ANSI and ASME standard?

A:Yes, our pump compliant with ISO / ASME/ANSI standard.

Q:How to customize pumps and mechanical seals ?

A:Customers could send us application data, we will select suitable pump and seal types, or client could send us drawings, We are well in OEM and ODM.

Q:How can I pay for my items? What is the payment you can provide?

A:Usually by T/T, 30% down payment once PI confirmed, the balance will be paid after inspection and before shipment. L/C at sight

Q:How long is warranty?

A:1 year for main construction warranty.

Q:How long is production lead time?

A:Normally 25 days. If client need urgently, we have a huge spare parts stock, we could finish assembly and testing in 7-15 days.

Q:What is the shipping terms you can provide?

A:Depnends on customer's requirements, we can provide different transportantin terms, such as EXW, FOB, CIF.

Q:Who is in charge of after-sales?

A:Boda Pump has professional after sales service team, we will follow up the client's comments and suggest them good solutions. Solve client's problems and keeping the clients profit.